Oversight

Oversight

While our executives determine the strategic goals for Boise Cascade, local management determines how we go about achieving them. In our Wood Products division, this involves safety committees that develop policies for their locations.

Where possible, we encourage the use of a safety team structure in which employees participate in smaller sub-committee groups focused on specific safety initiatives. Rather than the traditional centralized committee that is more broadly focused, this approach is intended to keep employees actively participating and breaking down barriers to compliance.

In our Building Materials Distribution (BMD) division, a high-level plan called the “Essential 8” sets governance expectations and includes accountability for both management and non-management employees. A Safety Strategy Toolbox helps facilitate implementation of the categories identified in the Essential 8 plan. For example, the first tool identified as “Leadership Committed to Zero” outlines the roles and responsibilities of every level of leadership in BMD.

In all of our divisions, regular and variable audits occur to ensure investigations are completed and corrective actions have been taken. Audit results are shared with the location’s site and operations managers, regional management, and the division’s operations and safety managers.

Compliance

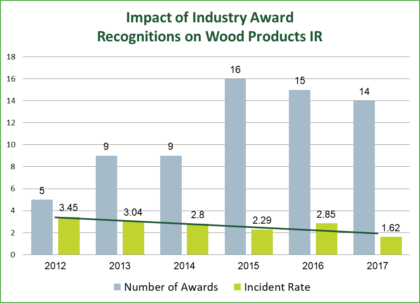

Boise Cascade discloses our OSHA 300A log results to OSHA yearly. We report our incident rate and severity rate history in our Wood Products division to a third-party trade partner, the APA – The Engineered Wood Association. They act as a code and regulatory liaison, provide product certification and testing, share the newest research on product standards, collect industry statistics, and represent manufacturers of structural engineered wood products.

The Wood Products division is in the process of implementing an ANSI Z10 compliant safety management system. Starting with risk assessment in 2019, we will establish policies that specifically address improving occupational health and safety.

Awards & Certifications

While we will always meet compliance standards to Federal and State regulations for worker safety, these regulations are our minimum standard. Wherever possible, we exceed those standards by participating in voluntary certification programs.

The Occupational Safety and Health Administration (OSHA) established the Voluntary Protection Programs (VPP) to recognize and promote effective workplace safety and health management systems. In the VPP, management, labor, and OSHA establish cooperative relationships at workplaces that have implemented comprehensive safety and health management systems.

The Occupational Safety and Health Administration (OSHA) established the Voluntary Protection Programs (VPP) to recognize and promote effective workplace safety and health management systems. In the VPP, management, labor, and OSHA establish cooperative relationships at workplaces that have implemented comprehensive safety and health management systems.

Boise Cascade’s Wood Products division has achieved recognition by both Federal and State regulatory agencies for their dedication to maintaining the highest standards in safety. The following operations have been accepted into the prestigious Federal OSHA VPP and Oregon State safety recognition programs. We continue on the journey to having all of our operations recognized by the regulatory agencies for their safety excellence.

OSHA Voluntary Protection Program (VPP):

- Alexandria, Louisiana – EWP plant

- Florien, Louisiana – plywood plant

- Oakdale, Louisiana – plywood plant

Oregon Safety and Health Achievement Recognition Program (SHARP):

- Medford, Oregon – plywood plant

- White City, Oregon – EWP plant

- White City, Oregon – log yard

- White City, Oregon – veneer plant

- Willamina, Oregon – veneer plant

We celebrate and recognize locations with achievements for not incurring any OSHA recordable injuries.

Our Medford Plywood Powerhouse celebrated just such an outstanding safety accomplishment in 2018. In addition to zeroing in on 15 years without a recordable injury, the crew surpassed the 54-year mark since the last lost-time injury incident.

Since the Powerhouse operates 24 hours a day, 7 days a week, this kind of achievement would not be possible without a focused commitment to safety. Their attention to working safely and looking out for each other, relentless adherence to protocol despite extreme temperatures and pressures, and vigorous attention to process improvement opportunities have set a remarkable example of what can be achieved in safety.

Also, in our Building Materials Distribution division, we have an Exemplary Safety Leadership recognition award with six identified safety leadership categories. To qualify for this prestigious award, recipients must meet consistent leadership in at least two of the six categories. In 2018, we recognized 26 individuals, which is an increase from 18 in the previous year.